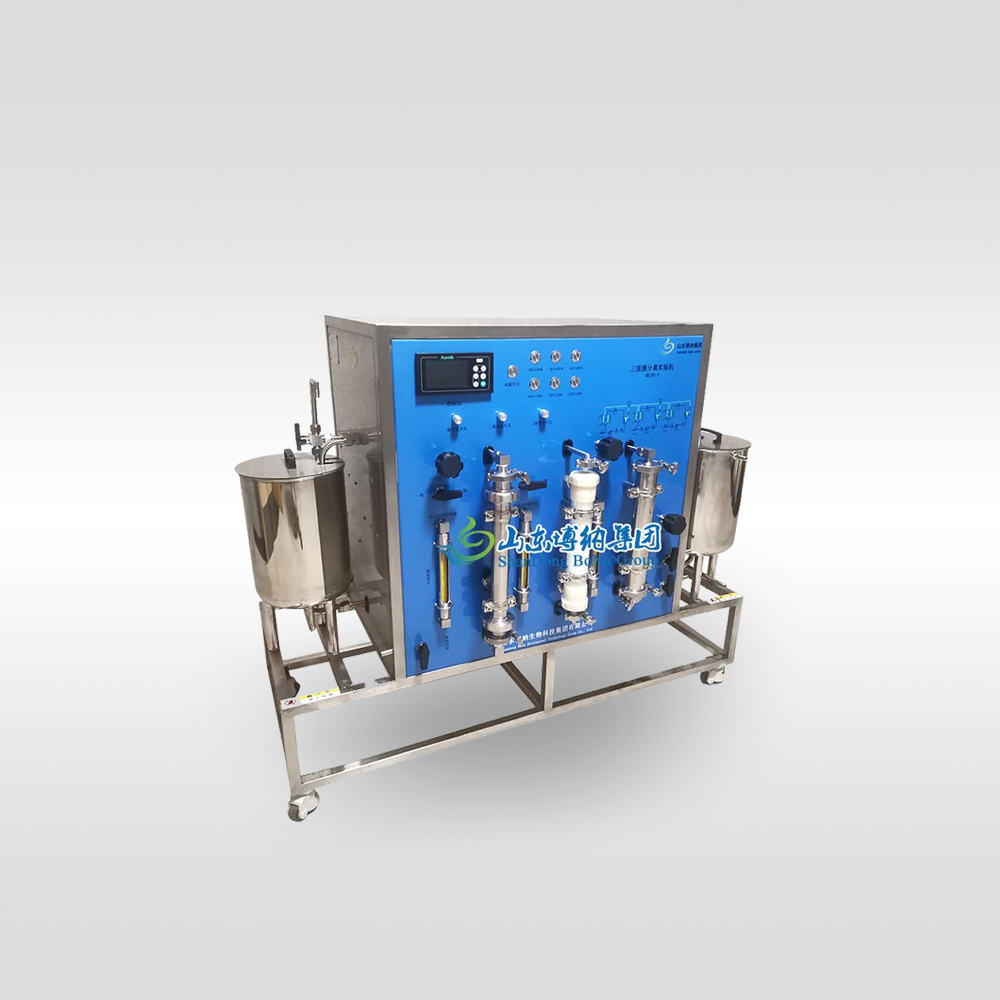

Three-Stage Membrane Filtration Experimental Machine BONA-DMJ60-3

|

No |

Item |

Data |

|

1 |

Product Name |

Three-Stage Membrane Filtration Experimental Machine |

|

2 |

Model No. |

BONA-DMJ60-3 |

|

3 |

Filtration Precision |

MF/UF/NF/RO |

|

4 |

Filtration Rate |

0.5-20L/H |

|

5 |

Minimum Circulating Volume |

0.5L |

|

6 |

Feed Tank |

5L |

|

7 |

Design Pressure |

- |

|

8 |

Working Pressure |

≤ 1.5MPa |

|

9 |

PH Range |

2-12 |

|

10 |

Working Temperature |

5-55℃ |

|

11 |

Total Power |

1500W |

|

12 |

Machine Material |

SUS304/ 316L/ Customized |

1. The flow range of the pump is configured according to the flow rate of the membrane surface of the sanitary membrane element, which can ensure that the experimental parameters selected by the experimental equipment can be directly put into industrial production.

2. The membrane housing is designed according to the fluid dynamics, which fully guarantees the flow velocity of the membrane surface and ensures the stability and reliability of the test data.

3. With automatic over-pressure protection function, over-pressure automatic shutdown, to ensure the safety of the using process.

4. With a temperature control module, over-temperature automatic shutdown to ensure the stability of materials during the experiment; high and low temperature alarms can be set to automatically start and stop; timer start and stop functions can be set.

5. Can be replaced with other types of organic microfiltration, ultrafiltration, nanofiltration membrane elements.

6. All stainless steel welding adopts automatic argon filling protection, single-sided welding, double-sided forming, the inner and outer surfaces of the pipeline are of good quality, and there is no welding point in the pipeline in contact with the material, ensuring the pressure and corrosion resistance of the equipment, the equipment is simple to operate, clean, hygienic, safe and reliable.

1. Independently completed a number of domestic and foreign membrane equipment projects, with rich experience.

2. BONA Has a group of senior engineers in membrane engineering applications, with many years of technology development and engineering practice.

3. BONA provide professional online video technical support.

4. Perfect customer service system, regular return visits, and guaranteed equipment quality.

5. BONA has a service center to provide with fast, efficient and affordable instrument maintenance services.