Membrane Industrial Machine

-

Hollow Membrane Industrial Machine BNMF803-A

BONA small experimental hollow fiber membrane equipment membrane element can be replaced with various molecular weight cut-off hollow fiber membrane elements (UF, MF). It is widely used in biological, pharmaceutical, food, chemical, environmental protection and other fields, and it can be used for process experiments such as separation, purification, clarification, and sterilization of feed liquid.

-

Hollow Membrane Industrial Machine BONA610-M

BONA6010-M is a Industrial scale Hollow Fiber Membrane Filtration system, can be used for process experiments such as separation, purification, clarification, and sterilization of feed liquid biological, pharmaceutical, food, chemical, environmental protection and other fields, and the membrane element can be replaced with various molecular weight cut-off hollow fiber membrane elements (UF, MF).

-

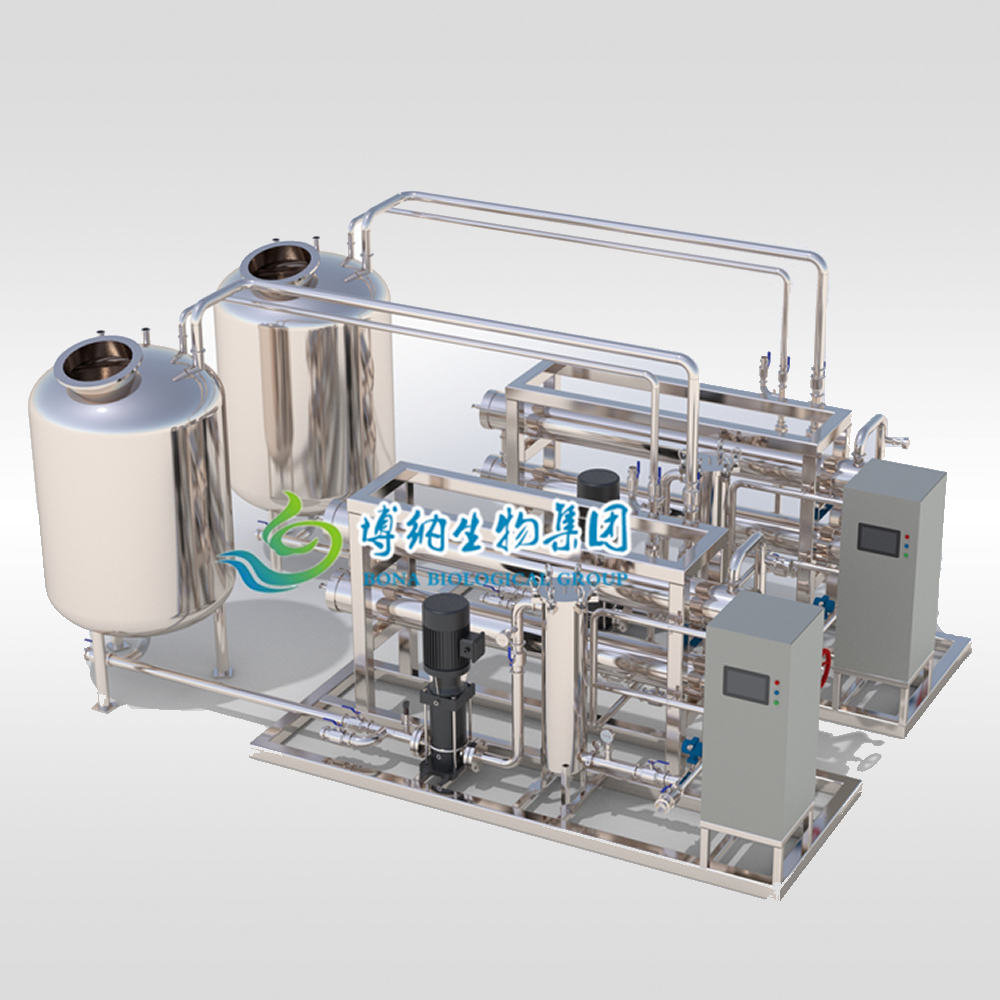

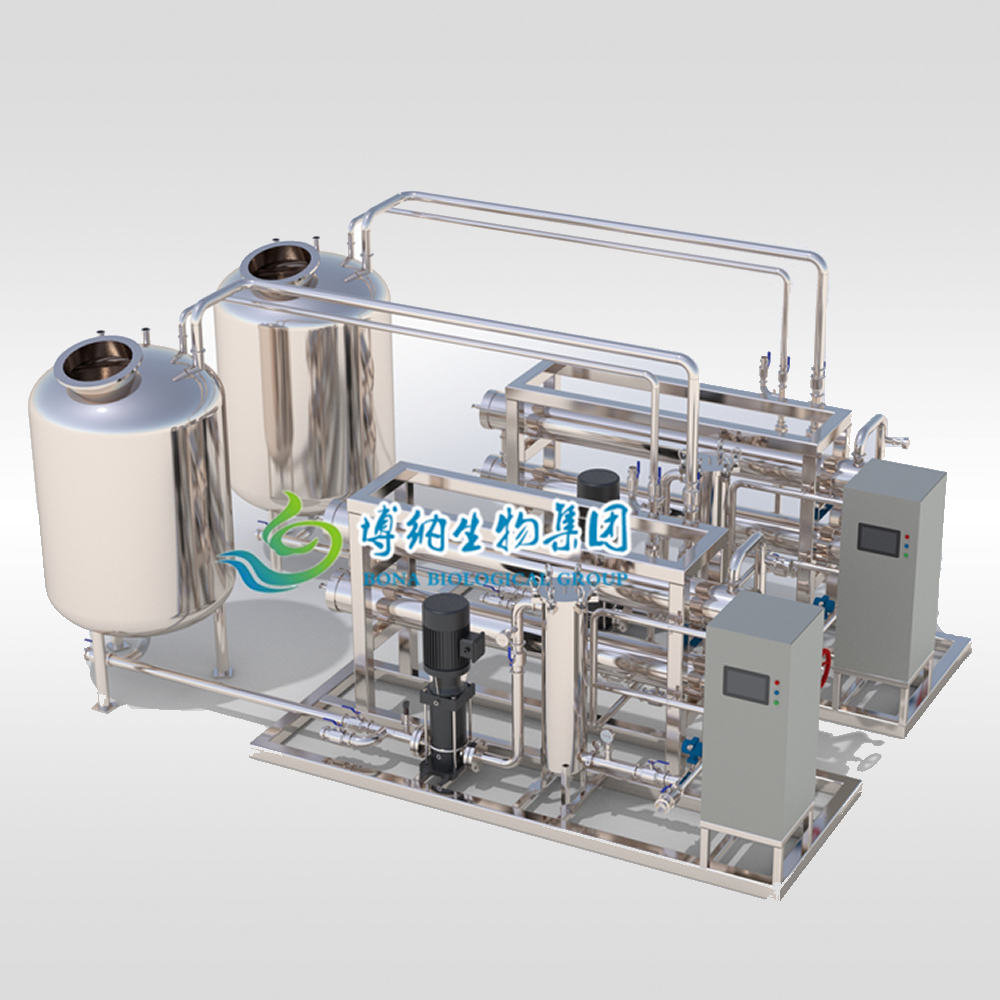

Continous Production Organic Membrane Machine BNNF 816-4-M

BNNF816-4-A Organic Ultrafiltration Membrane System is an automatic control continuous production type Industrial Scale production equipment, for the clarification, separation, and concentration of different feed liquid in Food and beverage, bio-pharm, cosmetics, chemical, water treatments and other industries. The main components of this system include feed pump, slag discharge pump, membrane module, cleaning tank, control cabinet and system pipeline, etc.

-

Continous Production Organic Membrane Industrial Machine BNNF 840-10-A

The BNNF840-10-A Organic Membrane System is an automatic control continuous production type Industrial scale production equipment, for the filtration, separation, and concentration of different feed liquid in food and beverage, bio-pharm, cosmetics, chemical, water treatments and other industries.1234+in the production process of biological fermentation/alcoholic beverages/Chinese medicine extraction/animal and plant extraction. The main components of this system include circulating pump, feed pump, slag discharge pump, membrane module, cleaning tank, control cabinet and system pipeline, etc.

-

Organic Membrane Industrial Machine BNUF 404-2-A

The BNUF404-2-A Organic Membrane System is an automatic control type Industrial Scale production equipment, for the clarification, separation, and concentration of different feed liquid in Food and beverage, bio-pharm, cosmetics, chemical, water treatments and other industries.

-

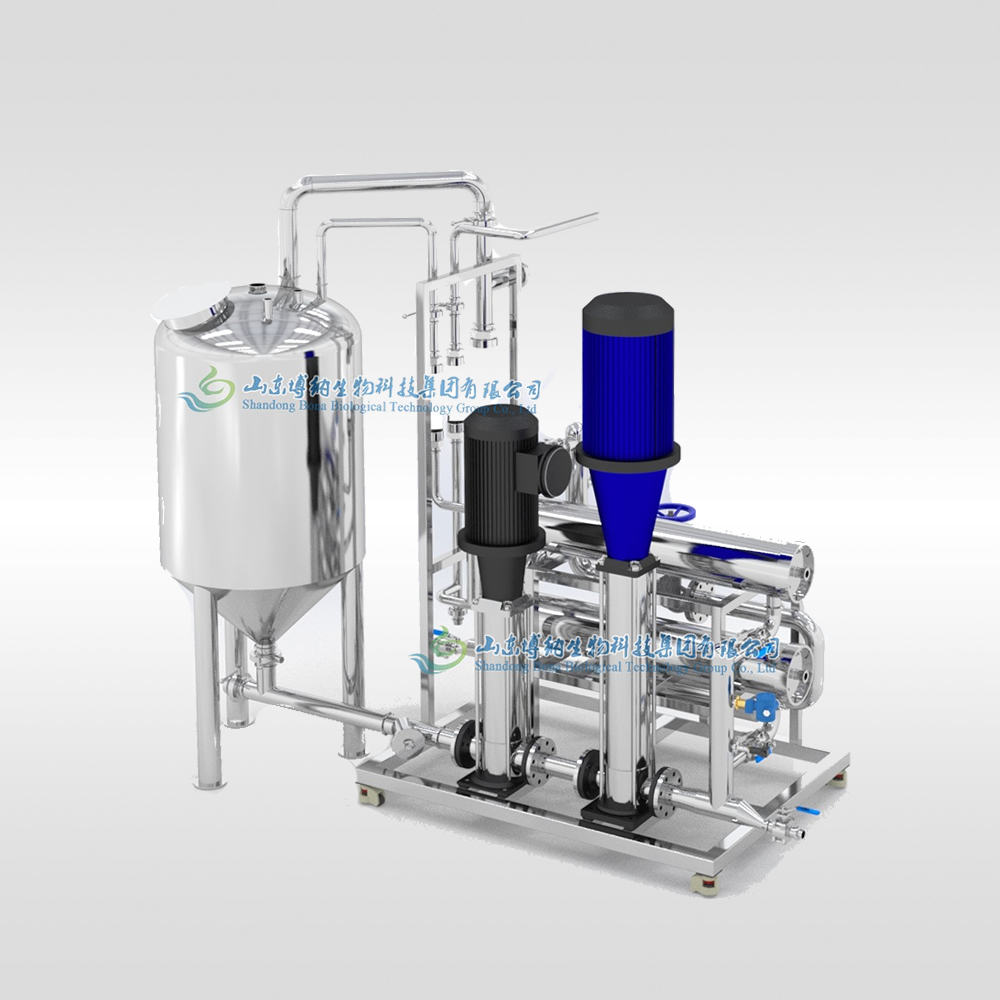

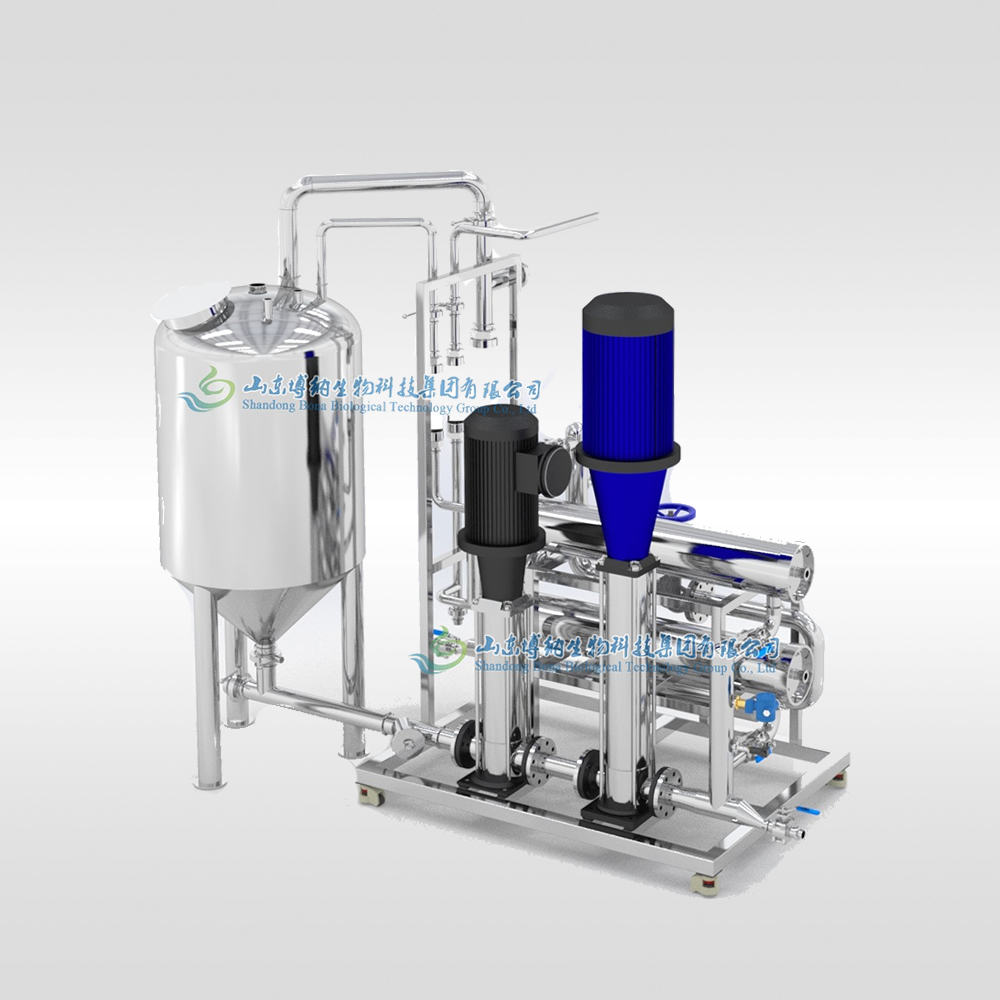

Organic Membrane Industrial Machine BNUF-804-2-M

BNUF804-2-M Organic Ultrafiltration Membrane System is an manual control type Industrial Scale production equipment, for the clarification, separation, and concentration of different feed liquid in Food and beverage, bio-pharm, cosmetics, chemical, water treatments and other industries. The main components of this system include feed pump, slag discharge pump, membrane module, cleaning tank, control cabinet and system pipeline, etc.

-

Ceramic Membrane Industrial System BNCM91-6-A

The BNCM91-6-A Ceramic Membrane System is an automatic control type Industrial Scale production equipment. The equipment consists of six 91-core membrane modules, each equipped with 91 ceramic membrane elements (can be replaced with 5nm-1500nm ceramic membrane elements), which can be used for the production of processes such as concentration, separation, purification and clarification of material and liquid. The main components of this system include feeding pump, circulating pump, slag discharge pump, ceramic membrane module, control cabinet and system pipeline, cleaning tank, etc.

-

Ceramic Membrane Industrial System BNCM61-6-M

The BNCM61-6-A is an automatic control type Industrial production equipment. The equipment consists of six 61-core membrane modules, each of which is equipped with 61 ceramic membrane elements, which can be used for the production of processes such as clarification, concentration, separation, purification of the feed in many industries. The ceramic membrane elements can be replaced with 5nm-1500nm pore size ceramic membrane elements. The main components of this system include feeding pump, circulating pump, slag discharge pump, ceramic membrane module, control cabinet and system pipeline, cleaning tank, etc.

-

Ceramic Membrane Industrial System BNCM37-6-A

BNCM37-6-A is an automatic control type Industrial production Ceramic membrane filtration system. The equipment consists of six 37-core membrane modules, each of which is equipped with 37 ceramic membrane elements, which can be used for the production of processes such as concentration, separation, purification and clarification of material and liquid. This set of equipment can be replaced with 5nm-1500nm ceramic membrane elements. The main components of this system include feeding pump, circulating pump, slag discharge pump, ceramic membrane module, control cabinet and system pipeline, cleaning tank, etc.

-

Ceramic Membrane Industrial System BNCM19-4-A

The system BNCM19-4-A is an automatic control type production equipment. The equipment consists of four 19-core membrane modules, each of which is equipped with 19 ceramic membrane elements, which can be used for the production of processes such as concentration, separation, purification and clarification of material and liquid. This set of equipment can be replaced with 5nm-1500nm ceramic membrane elements. The main components of this system include feeding pump, circulating pump, slag discharge pump, ceramic membrane module, control cabinet and system pipeline, circulating tank, cleaning tank, etc.