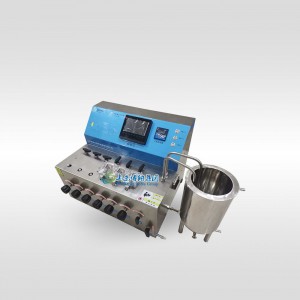

High Pressure Flat Sheet Membrane Filtration Lab Machine BONA-TYLG-19

|

No |

Item |

Data |

|

1 |

Product Name |

High Pressure Flat Sheet Membrane Filtration Lab Machine |

|

2 |

Model No. |

BONA-TYLG-19 |

|

3 |

Filtration Precision |

MF/UF/NF/RO |

|

4 |

Filtration Rate |

- |

|

5 |

Minimum Circulating Volume |

0.5L |

|

6 |

Feed Tank |

1.1L |

|

7 |

Design Pressure |

- |

|

8 |

Working Pressure |

≤ 4.0/ 6.5MPa |

|

9 |

PH Range |

2-12 |

|

10 |

Working Temperature |

5-55℃ |

|

11 |

Total Power |

1500W |

|

12 |

Machine Material |

SUS304/316L/Customized |

|

MF Membrane |

0.05um, 0.1um, 0.2um, 0.3um, 0.45um |

|

UF Membrane |

1000D, 2000D, 3000D, 5000D, 8000D, 10KD, 20KD, 30KD, 50KD, 70KD, 100KD, 300KD, 500KD, 800KD |

|

NF Membrane |

100D, 150D, 200D, 300D, 500D, 600D, 800D |

|

RO Membrane |

RO1, RO2, RO3, RO4, RO5, RO6, RO7, SW30, BW30 |

1. The membrane concentration polarization and membrane surface pollution are not easy to happen due to the cross flow filtration, and the filtration rate attenuation is slowly, which can realize long time filtration.

2. The membrane separation process is carried out at room temperature, especially for the experiment of thermosensitive substances.

3. The inner and outer surfaces of the pipeline are of good quality, and the whole set of equipment materials contact the pipeline without any welding points, which ensures the pressure resistance and corrosion resistance of the equipment, simple operation, cleanliness, hygiene, safety and reliability.

4. The pump adopts pressure sensing system and frequency conversion control system, which can adjust the pressure and flow by frequency conversion, and it can set the ideal pressure.

5. Designed according to fluid dynamics to ensure tangential flow and turbulent flow in the membrane test cell, and ensure the reliability and stability of test data.

6. It can be installed with microfiltration membrane, ultrafiltration membrane, nanofiltration membrane and reverse osmosis membrane, which is suitable for membrane test research and filtration experiment of a small amount of feed liquid.

7. The jacketed material tank can be connected to a high and low temperature circulation device for temperature control.

8. The equipment is equipped with a digital pressure sensor with an accuracy of 0.4%FS. It can accurately record the test high pressure and low pressure data, ensure the accuracy of the data, and overcome the defect of the low precision of the mechanical pressure gauge.

9. The equipment can set the pressure, and make automatic constant pressure control by the constant pressure control system to prevent the equipment boosting automatically during the test.

10. The pressure and temperature of the equipment are digitally displayed, and the sensor value is displayed on the screen, which can be displayed in a centralized manner, and can be uploaded to the computer as needed to record the data during the test.

11. With over-temperature automatic protection system, over-temperature automatic alarm and shutdown.

12. The membrane cell adopts a parallel structure, any one or several of them can be used for experiments, and different membranes can be installed at the same time for simultaneous testing to ensure the consistency of feed flow and state.

1. Independently completed a number of domestic and foreign membrane equipment projects, with rich experience.

2. BONA Has a group of senior engineers in membrane engineering applications, with many years of technology development and engineering practice.

3. BONA provide professional online video technical support.

4. Perfect customer service system, regular return visits, and guaranteed equipment quality.

5. BONA has a service center to provide with fast, efficient and affordable instrument maintenance services.