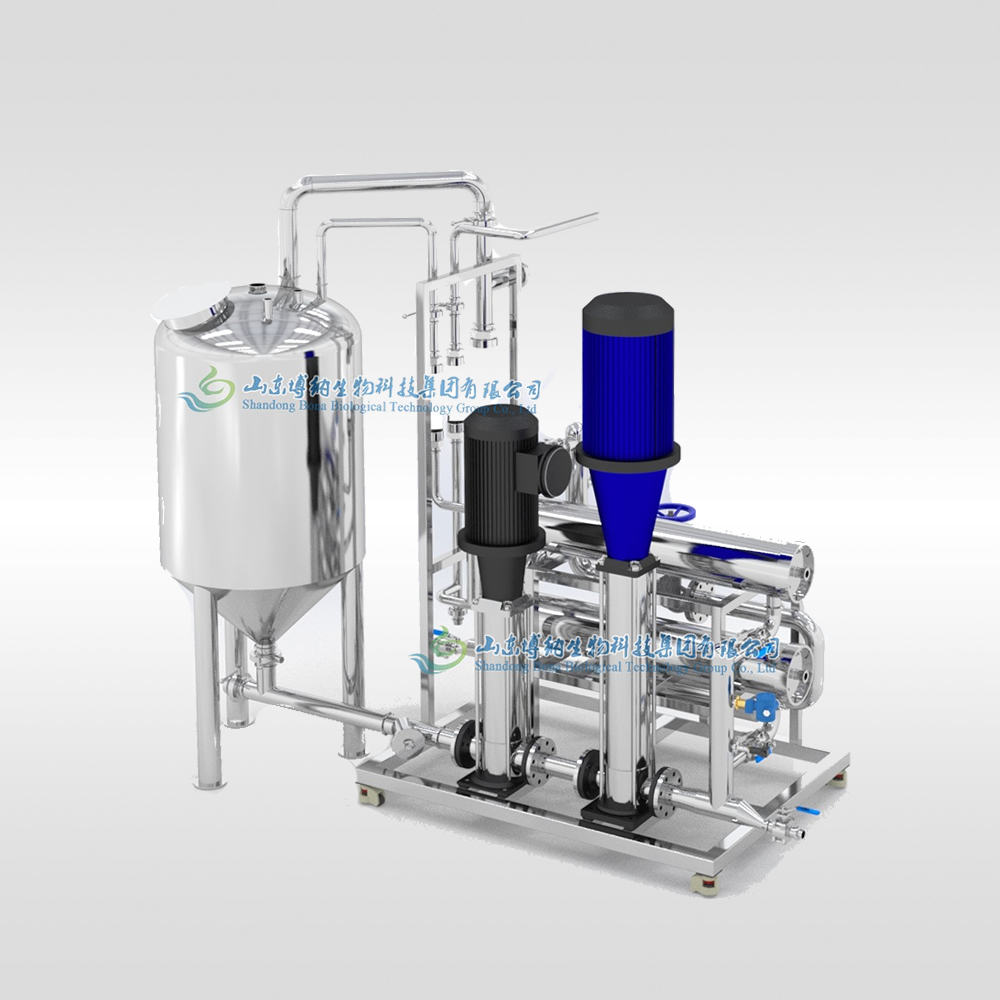

Organic Membrane Industrial Machine BNUF-804-2-M

|

No |

Item |

Data |

|

1 |

Model no. | BNUF-804-2-M |

|

2 |

Filtration area | ≥80m2 |

|

3 |

Filtration Precision | UF |

|

4 |

Working temperature | 5 - 55℃ |

|

5 |

Working pressure | 0-8bar |

|

6 |

pH range | 2-11 |

|

7 |

Total Power | 20 Kw |

|

8 |

Material of overflow | SUS304 |

|

9 |

Mode of control | Manual / PLC Automatic control |

|

10 |

Membrane element | Composite membrane |

| Material: PES or other | ||

| pH:2-11 | ||

| Size: 8.0’×40’ | ||

|

11 |

Structure of system | Integrated structure. |

|

12 |

Power demand | AC/380V/50HZ or as required |

|

13 |

Cleaning water | Soften water/purified water, suggested: SiO2≤10ppm, Mn≤0.02ppm, Fe≤0.05ppm, pH=6-8, Ca hardness≤50ppm |

1. The quality of pipeline internal and external surface is excellent. The welding parts adopts automatic argon filling protection, single side welding and double side forming welding. To ensure the pressure resistance and corrosion resistance of the equipment.

2. The system is made of sanitary stainless steel, the inner and outer surfaces of stainless steel components and connecting pipes are pickled, the outer surfaces of components and pipes are smooth and clean, and the internal welds are smooth and free of solid foreign matter such as welding slag. fully enclosed pipeline operation, and the site is clean and sanitary, meeting the requirements of GMP or FDA production specifications.

3. Use High quality ultrafiltration membrane elements to ensure interception performance and membrane flux. Can meet the different filtration requirements of customers;

4. The overall layout of the equipment is reasonable, beautiful. System is simple to operate, clean, safe and reliable. Easy to clean and maintain;

5. It is carried out at normal temperature under mild conditions without component damage, especially suitable for heat sensitive substances; It can realize efficient separation, purification and high multiple concentration of materials.

6. Integrated design, convenient for elements replacement, online regeneration, cleaning and sewage discharge device, reduce labor intensity and production cost and improve production efficiency;

6. The control system can be personalized designed according to the user's specific use requirements, and the important process operation parameters can be monitored online on site to avoid manual misoperation and ensure the long-term stable operation of the system.

1. It can used in blood treatment, wastewater treatment and ultrapure water preparation;

2. It is used to separate bacteria, heat sources, colloids, suspended solids and macromolecular organics in industrial water;

3. Concentration, purification and clarification of fermentation, enzyme preparation industry and pharmaceutical industry;

4. Juice concentration and separation;

5. Separation, concentration and clarification of soybeans, dairy products, sugar making, Wine, tea, vinegar, etc;

6. Used for separating, concentrating and purifying biological products, pharmaceutical products and food and beverage.