Organic acids are widely exacted in the leaves, roots and especially fruits of Chinese herbal medicines. The most common acids are carboxylic acids, the acidity of which originates from the carboxyl group (-COOH). Many organic acids are important basic chemical raw materials, such as citric acid, dibasic acid, lactic acid, itaconic acid and so on. With the increasing demand for organic acids, how to reduce production costs, improve product quality, and save energy and reduce emissions has become the focus of enterprises. Therefore, optimizing the extraction process of organic acids has become one of the main competitive means for organic acid manufacturers. Today, the editor of Shandong Bona Group will introduce the application of membrane separation technology in the production of organic acids.

As one of the pretreatment technologies for the separation and extraction of citric acid, ultrafiltration technology is a new method that only appeared in recent years. It is a simple physical screening process. It can be used to remove and separate impurities such as proteins, sugars, and pigments in the filtrate. The key to this method is to choose ultrafiltration membranes with better oxidation resistance and acid resistance. Membrane separation and filtration of organic acid fermentation broth to completely remove macromolecular proteins, colloids, bacteria, polysaccharides and other impurities in the fermentation broth at the molecular level. The filtrate has high clarity and high purity of organic acids. It's conducive to the control of subsequent sewage and improve product quality and yield.

The process of extracting organic acid by ultrafiltration method:

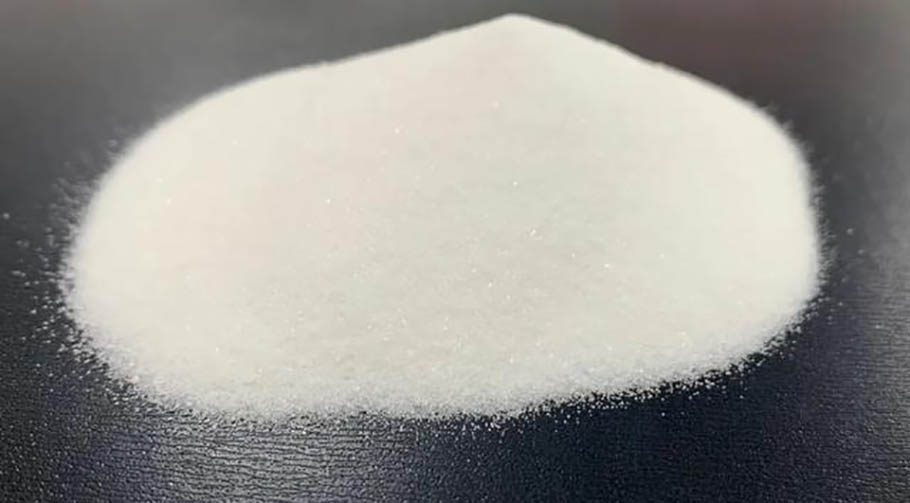

Organic acid fermentation broth pretreatment→ultrafiltration→crystallization→centrifuged mother liquor→drying→finished product

Advantages of organic acid membrane separation technology:

1. Membrane separation technology replaces the traditional plate-and-frame filtration method, clarifies the fermentation broth, improves the quality of the filtrate, and reduces resin pollution in the subsequent sequence;

2. The membrane equipment operates at room temperature, saving energy without destroying the active ingredients in the product;

3. There is no need to add chemicals, solvents, and secondary pollutants in the filtration process;

4. Membrane system materials are all made of food hygiene grade stainless steel, fully enclosed pipeline operation, and meet the requirements of GMP production specifications. The system adopts integrated process design, which occupies less floor space and has a reasonable layout;

5. Membrane materials and auxiliary equipment materials are non-polluting materials, in line with QS and GMP requirements.

Bona Bio is a manufacturer specializing in the production of membrane separation equipment. It has many years of production and technical experience, focusing on solving the problem of filtration and concentration in the production process of biological fermentation / beverage / traditional Chinese medicine / animal and plant extraction. Circular production methods can effectively help customers improve production efficiency and achieve cleaner production. If you faced any problems in membrane filtration, please feel free to contact us, we will have professional technicians to answer for you.

Post time: Apr-20-2022